To the left of the dam are a couple of AxialDrain lines that kept fluids from building up underneath the body of the DoubleTube Barrier section.

Repair the Dam and Protect the Stream

“Stop the discharge flow, but don’t stop the stream flow for more than two hours...” That was one of several mandates given to the City of Ukiah in early-2001 by a variety of government and regulatory agencies in Northern California. The discharge flow from the dam had to be stopped to facilitate the repair of the concrete plenum for the Lake Mendocino Hydroelectric Power Plant just below Coyote Dam in Mendocino County. The discharge flow could not be stopped for more than two hours because Lake Mendocino supplies water vital to the survival of the East Fork of the Russian River, an important tributary within the midst of a vibrant, yet delicately balanced ecosystem along the north coast of California. Under the federal Endangered Species Act (ESA), the Russian River watershed is designated as critical habitat for threatened stocks of Coho salmon, steelhead, and Chinook salmon. Federal agencies, such as the U.S. Army Corps of Engineers that control the discharge flow from Coyote Dam, must ensure their actions will not adversely affect critical habitat.

The Lake Mendocino Hydroelectric Power Plant just below Coyote Dam in Mendocino County, CA. Up inside the concrete walled spillway in the center of the image is where the damaged plenum structure was located.

Russian River Watershed

This spectacular region of our nation’s most populous state encompasses many hundreds of square miles of rich agricultural land, pristine coastal marine environments, industrial and commercial real estate developments, as well as a population of close to 750,000 people. Interdependent communities of fish, marine wildlife and plant life within the Russian River watershed are totally reliant upon the waters that flow southward from Lake Mendocino and eventually empty into the Pacific Ocean. Equally dependent upon these same waters for their sustenance and support are the members of the downstream community in Lake, Mendocino and Sonoma counties (recreational water users, vintners, dairy, vegetable and grape farmers, et al).

Excess Regulations or Appropriate Controls?

Regulators and government officials from the National Marine Fisheries Service, the United States Army Corps of Engineers, the Sonoma County Water Agency, the California Department of Fish and Game, the United States Geological Survey and the City of Ukiah had plenty to discuss when it came time to submit the variety of documents required for this project to get underway. According to Ann Burck, project manager for the repair work for the City of Ukiah: “Over a several month period of time it seemed like there was a never-ending series of regulatory hoops we were required to jump through.” However by working together with a team of regulators, consultants, engineers, hydrologists, technicians, laborers and other ‘officials’, Mrs. Burck was eventually able to satisfy all the regulatory requirements and the demands placed upon her.

Time to Fix a Plenum Plate - Again . . .

In early-1998, there was a feeling of deja vu when the steel noseplate attached to one of the concrete plenum structures for the Lake Mendocino Hydroelectric Power Plant was torn away from its anchorage and destroyed. This section of the Coyote Dam outlet had been damaged and repaired more than once since the plant (with its 1,000-kilowatt and 2,500-kilowatt turbine/generator units) became operational in 1986. For the first repair in 1989, the discharge flow was stopped for the duration of the repair. However, in 1993 when the reattached plate came off again, Chinook salmon in the Russian River were on the threatened species list and new regulations governed discharge flows into the river. Instead of days, now the discharge flow could be stopped only long enough to install a large steel diversion wall, 5 feet high and 40 feet long. To complete this operation several city staff worked non-stop for 10 to 12 hours.

Do the Same Work in Less Time . . .

By 1998, two more fish in the Russian River were on the threatened species list and environmental regulations had changed again and quite dramatically. The National Marine Fisheries Service under the federal mandate of the Endangered Species Act established new policies. Discharge flow into the East Fork of the Russian River could be interrupted for no more than two hours, not the 10 to 12 hours previously permitted and only if there was sufficient water available in the river north of the confluence. Detailed operational procedures with supporting documentation had to be submitted and implemented during the ‘zero flow’ period. Ms. Burck headed back to the drawing board to develop a plan that would require much less time from start to finish.

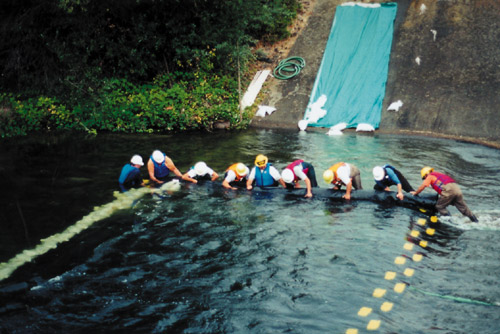

Above: A 10-man crew can be seen rolling-up the 4-foot by 80-foot cofferdam onto a 4-inch by 6-inch Douglas Fir timber in preparation for placing it in the 'live' stream channel. Below: The discharge flows from the Coyote Dam were running at approximately 150 cfs at a depth of about 26-inches during the cofferdam installation. The entire underwater installation took about 1 hour to complete.

The World Wide Web Leads to a Solution

Ms. Burck utilized the resources available at her fingertips by searching the Internet for “construction job site dewatering”. That is how she discovered that less than 200 miles north of Ukiah (in Arcata, California) there was a small company who manufactured and installed pressure-secured temporary water-filled cofferdams. When Ms. Burck explained her situation to them, she learned that a 2-foot high by 42-foot long version of their product could dewater the work area around the damaged outlet conduit structure inside Coyote Dam - in less than two hours! But it was not time to celebrate just yet. There were still more of the never-ending series of regulatory hoops to jump through.

How About Storing Some Water?

In the world of regulators, contingency planners and safety analysts it seems like there is never enough redundancy. In the world of endangered species protection redundancy is a byword of the trade. A method to dewater the worksite that could be installed in two hours had been found, but would that also provide enough time for staging of equipment and supplies? The new ESA policies were intractable, water flow had to be reestablished after two hours, no longer. How could more time with ‘zero flow’ discharge from the dam be achieved in case it was needed?

The solution Ann Burck found was to store additional acre-feet of water below the dam outlet before the discharge flow was stopped. This stored water could then be released at a greatly reduced rate of flow into the stream channel for perhaps 60 minutes. At that rate, fingerlings, juvenile-aged fish and other marine life forms would be provided with enough water to keep them alive.

How to Store Additional Water Without Stopping Stream Flow

There were six basic criteria to fulfill to safely pond up the additional volume of stored water required to extend the 2-hour window of time. Without interrupting the downstream flow of water a device had to:

- Be able to be installed in a live stream channel on top of a concrete weir;

- Have the ability to pond up a measured amount of stored water by slowly raising the crest height of the device (and thus the elevation of the pond);

- Reach its intended height and length and remain safe and stable throughout the installation, inflation and water storage process;

- Remain in position within the stream channel and maintain the volume of stored water for release later;

- Be able to release overtop of the device, and back into the natural stream channel, a minimum amount of water (sufficient to keep the fish, wildlife and plant life in the downstream community alive and well) for up to 1-hour;

- Have the ability to be lowered down and emptied, in a safe, easily controlled manner and subsequently removed from the stream channel without causing any significant release of sedimentary materials, soil fines, debris and/or other substances that might compromise the health and clarity of the downstream aquatic environment.

Over the next several weeks a plan of action was developed (with city staff, government agency regulators and private industry consultants) to address each requirement listed above.

'Anti-oscillation Fins' help to stabilize the pressure-secured temporary water-filled cofferdam while water is flowing overtop the structure.

A key component of this strategy would be a second pressure-secured temporary water-filled cofferdam (4-feet high by 80-feet long) designed to be deployed in the ‘live’ stream channel (prior to the shut-off of the primary flows from Coyote Dam). Using this type of water diversion structure would facilitate the storage of the ‘extra’ water potentially needed to keep the downstream community members alive and well beyond the mandated 2-hour ‘zero flow’ time limit.

PressureSecured dam technology utilizes the weight of the ponded water on the upstream side of the water-filled barrrier tubes as an additional means of ‘anchoring’ the structure to the substrate materials upon which the unit is deployed. They can be safely installed in streams, rivers, lakes, tidelands, concrete or asphalt channels, grasslands, as well as many other areas.

The need to keep the stream flowing during the installation of this diversion structure, and during the release of the stored water in the zero flow period, required that “Anti-oscillation Fins’ be installed on this second unit. These fins (fabricated from PVC material and semi-rigid sections of 3/4-inch diameter PVC suction hose) helped to stabilize the dam when large volumes of water were allowed to overtop the DoubleTube barrier. Prior to being rolled up in preparation for deployment, two rows of fins are bonded to the body of the dam with PVC adhesives.

Months of Preparation - Hours of Work

Once the project finally got underway Ann Burck’s actions over several months, and those of many others, accomplished the two primary goals they had set out to attain in a mere 72-hour time span.

The first goal they accomplished was of successfully repairing a damaged concrete plenum structure inside the spillway at the Lake Mendocino Hydroelectric Power Plant. The discharge flow into the East Fork of the Russian River was shut-off near the base of Coyote Dam by the United States Army Corps of Engineers at 9:00 a.m. on September 25, 2001. As soon as the water stopped flowing down the outlet conduit a 2-foot high by 42-foot long pressure-secured temporary water-filled cofferdam (a VanDuzen model Superior Dam) was installed in less than 2-hours time. This unit provided a dewatered construction zone inside the damaged outlet structure making it possible for the necessary repairs to be completed within the next 48-hours.

Secondly, they accomplished their goal of protecting the vibrant, yet delicately balanced ecosystem along the north coast of California fed by the East Fork of the Russian River. On September 24, 2001, the day before the stream flow was shut-off near the base of Coyote Dam, a 4-foot high by 80-foot long pressure-secured temporary water-filled cofferdam (another VanDuzen model Superior Dam) was installed on top of a concrete weir structure approximately 150-yards below the spillway construction repair site. This unit was deployed in less than 1-hour without interrupting the downstream flow of water and the ‘extra’ stored water was ponded up behind it in a little under 3-hours time.

Once the construction repair process was begun the following morning, it became evident that more time than the allotted 2-hours of ‘zero flow’ was going to be required to complete all of the work ‘in the dry’ that had to be done. Thus, at the appropriate time the crest of the 4-foot high by 80-foot long dam began to be lowered slowly and steadily - releasing just the right amount of flow into the natural stream channel. This provided for an additional 60-minutes of construction activities to be completed. A short time in a literal sense, yet a very important space of time from the perspective of the fish, marine wildlife and plant life inhabiting the Russian River watershed below Lake Mendocino.

Teamwork Leads to Success

No one device, or any one person, was more or less responsible for the successes attained on this project. There was a clearly apparent need for new technology, new ways of solving problems, and new ways of working together. Everyone who was a part of this project had an important role to play in the eventual outcome. A talented, creative and hard working group of men and women employed a combination of the latest technologies with that most intangible of assets, teamwork, to quite simply - save a stream and a hydroelectric plant. L&W

For more information contact: Paul Ennis, Sales and Production Manager, Superior Dam, LLC, 44 Sunny Brae Center, Arcata, CA 95521, Toll FREE: (866)432-3267 (Continental U.S.A. Only), Local & Int’l: (707)825-6688, fax (707)825-8265, Web Site: http://www.superiordam.com, e-mail: support@superiordam.com

|