Underground Stormwater Treatment System Meets BMP Requirements For Water Quality Enhancementby Ted DeVibiss, P.E. |

||

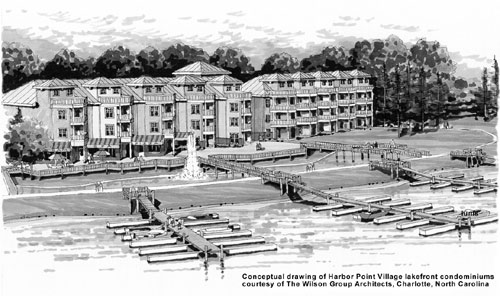

Harbor Point Village is a mixed-used lakefront development on a 6.8-acre tract in Mooresville, North Carolina. When completed, it will feature thirty new condominiums with swimming pool and sundecks, a restaurant, and three separate small commercial buildings. A marina facility will provide convenient boat access to Lake Norman, the state’s largest man-made lake. Because nearly half of this site will be converted to impervious surfaces such as roofs and parking lots, stormwater runoff will be substantially increased. In the past, the stormwater would have been discharged directly into Lake Norman. The lake is not only a popular water recreation site, but also serves as the primary water supply source for the City of Charlotte, North Carolina. National concerns over such “wet weather” discharges into surface waters stem from the possibility of harmful contamination. When stormwater runoff is not treated it can carry pollutants as well as trash and debris that are frequently deposited into downstream waters. Reducing the pollutant content in stormwater runoff is the objective of National Pollution Discharge Elimination System (NPDES) regulations enacted by the U.S. Environmental Protection Agency (EPA). The different phases of NPDES require that site developers and municipalities implement procedures called Best Management Practices (BMPs) aimed at controlling pollutants in stormwater runoff. For maximum effectiveness, state and local agencies are called upon to develop specific BMPs suitable to their regional geographic and climatic conditions. The initial stormwater management plans for Harbor Point Village involved a large on-site stormwater retention and treatment wet-pond. When site conditions permit, wet-ponds can be an effective means of enhancing water quality and for managing discharge rates into receiving water bodies or storm sewers. A typical wet-pond requires a sizeable water pool in which pollutants are separated from the captured runoff by natural processes resulting from water detention and the presence of aquatic plants. Given ample time between rainfall events, pollutants in ponded water settle to the bottom (for heavier-than-water particles) as sediment or float to the surface (for lighter substances). Unless disturbance causes reintroduction into the stormwater, sediment remains on the bottom of the pond and floating particles can be removed by skimming the surface.

Configuring the Harbor Point Village pond to meet State of North Carolina regulations for this type of watershed required a ‘permanent’ detention capacity of 194,500 gallons and allowance for an additional 46,400 gallons of ‘intermittent’ runoff. The ‘permanent’ capacity provides a relatively undisturbed storage environment for achieving optimum sedimentation and floatation of contaminants from captured stormwater. In some cases, pond designs employ natural soil filtration as secondary treatment to remove ultra-fine particles and some heavy metals that are not readily removed via sedimentation or floatation. Storage capacities are generally based upon anticipated runoff quantities that are estimated using such variables as impermeable surface area, intensity and duration of expected storm events, rainfall frequencies, and the capture time for contaminant removal.

The amount of building construction and parking lot area on the site limited the space available for the wet-pond to that between the condominiums and the lakeshore. Situating the proposed pond on this sloping terrain would require substantial earthwork, including the construction of a 230-foot long concrete block retaining wall near the condominiums. The estimated cost for building the wet-pond in this relatively restricted area was expensive and would not provide the amenities envisioned by project planners. This led the developer, The Ghazi Company of Charlotte, North Carolina to request alternative design proposals from the project engineers, GNA Design Associates, Inc., also of Charlotte, North Carolina.

Todd Fisher, P.E., Senior Civil Engineer with GNA Design Associates, Inc. says: “Coincidentally, we had recently attended a seminar on underground stormwater treatment facilities based upon large diameter corrugated steel pipe system. Such systems are often used for detention storage of stormwater from developed sites as an alternative to surface ponds. With provisions for pollutant removal, they can qualify as a Best Management Practice for enhancing stormwater runoff quality.”

State of North Carolina regulations established the design parameters, beginning with capturing the runoff from a designated storm event and minimum and maximum detention times of 24 hours and 120 hours respectively. These detention times in a quiescent environment are generally considered sufficient for removal of heavier sediments and floatable substances. This design time period provides for a repeat of the same storm event the following day. GNA Design Associates modeled rainfall events using a U.S. Corps of Engineers HEC-1 hydrology program to assist with determining the hydraulic requirements and storage capacities of the detention system.

The underground stormwater treatment facility for Harbor Point Village is primarily based on 96” diameter ALUMINIZED STEEL(tm) Type 2 corrugated steel pipe. Surface runoff entering the system is first detained within the 88-foot long sedimentation chamber, where gravitational forces separate heavier particles and floatable materials from the stormwater. Following this preliminary treatment, the captured water enters the 96” diameter filtration chambers. These chambers, with a total combined length of 312 lineal feet, have inverts covered with a combined filter/ drainage system comprised of select sand and stone encapsulated perforated collector pipes. This system also includes a 36” diameter CSP overflow bypass near its inlet, which will prevent flooding that may result from very high flow rates or unexpected plugging of the filter or drainage media. The 18” thick layer of well-graded filter sand conforms to North Carolina Department of Transportation specifications and is similar to ASTM C33 standard for fine aggregate except for lower fines content. Particle sizes range between 0.15 and 4.75 mm (0.006 and 0.20 inches respectively) with no more than 3% fines (passing the #200 U.S. Sieve). The state-specified drawdown period, along with the runoff volumes and sand filter flow-through rates, determined the required surface area of the filtration material. The sand filter assists with the removal of many small, lightweight pollutant particles remaining in the water after sedimentation. Larger collected debris will be removed via vacuum truck through the multiple access points designed for this purpose. The EPA recognizes sand filters of this type for the removal of certain pollutants commonly found in stormwater runoff. The drainage system includes a nonwoven geo- textile wrapping for the stone envelope and 4” perforated PVC drainage pipe. The #57 stone increases the drainage efficiency of the system. The nonwoven geotextile maintains separation of the stone and filtration sand, while minimizing the migration of small sand particles into the drainage media.

The filter sand and drainage system, which connect to a 6” outlet pipe where the four chambers meet, run continuously along the inverts of the filtration chamber piping. A 12” CSP discharge pipe directs treated water from the filtration chambers to the lake. The underground stormwater treatment system was manufactured by Contech Construction Products Inc. of Middletown, Ohio. Additionally, Contech’s A-2000™ perforated profile-wall PVC pipe was used to construct the drainage systems in the facility’s filtration chambers. Although surface detention ponds can be aesthetically desirable, they don’t allow full use of the land and can become attractive nuisances, creating safety concerns for children and others. Their long-term effectiveness also depends upon adequate maintenance. Underground stormwater treatment facilities also require periodic inspection and maintenance. The maintenance schedule developed by GNA Design Associates for the Harbor Point Village BMP facility contains these items and frequencies:

Stormwater treatment systems are becoming a necessity to prevent the unacceptable environmental impacts of runoff-borne pollutants on surface waters. Although a number of structural Best Management Practices are available, only some can manage the relatively large volumes from larger developments and provide adequate detention time. As an alternative to vegetated surface ponds and basins, underground corrugated steel pipe detention systems combined with approved filtration media can usually meet current pollutant control standards while easing maintenance and space requirements. For either new construction or for adding a runoff treatment facility to existing developments, these systems are designed to reduce the costs of implementation and compliance with stormwater discharge regulations on larger sites. For more information contact Mary Carmody, CONTECH, 1001 Grove Street, Middletown, OH 45044, (937)866-4914, fax (937)847-0007, e-mail: mcarmody@chisano.com, website: www.contech-cpi.com. |

©2003 - 1998 Land and Water, Inc.