Comparison of Erosion Control Technologies: “Blown Straw vs. Erosion Control Blankets, Quantification of Performance and Value”by Chad M. Lipscomb, Tony Johnson, Roy Nelsen and Tim Lancaster |

|

Introduction Challenges in providing adequate erosion control in the field require a diverse toolbox of solutions. BMPs refer to the individual tools available to the erosion control professional in stabilizing and minimizing soil erosion. Included in any standard toolbox of BMPs should be solutions intended to provide varying levels of performance and economy. In determining the most cost-effective solution to any particular field challenge, an understanding of the expected performance and overall value of alternative practices must be obtained. The ECTC has reviewed research for a series of BMPs to evaluate common technologies. Within the framework of a dedicated study, the practice typically referred to as “Blown Straw” and a typical, degradable RECP were compared. This article presents the results of the study which show RECPs as a more cost-effective BMP on steep slopes, compared to Blown Straw. Erosion Control Practices, Materials and Products One advantage RECPs offer specifiers, contractors and project owners is the level of confidence in the quality, consistency, and performance. Manufactured products are held to the highest standard of evaluation and regulation. Thus, manufactured products tend to be the most costly, however, most reliable tool in the toolbox. Manufactured products are designed and produced from various materials to meet the varying requirements and challenges found in the field. In particular, RECPs are available in a variety of compositions and roll sizes to provide maximum erosion protection, increased infiltration, and/or enhanced mulching capability. Further, RECPs are designed to have expected longevities ranging from forty-five days to over three years. Thus, RECPs can afford an erosion control professional an acceptable solution to nearly every design challenge. Conversely, Blown Straw has limited longevity, utilized only as a temporary practice. Materials such as loose straw and hydraulically applied mulch rely upon the contractor for consistent, uniform application and coverage of the soil surface. If the application of straw or mulch is inconsistent, the performance of the installation will be compromised. Table 1 Quantifying Costs Quantifying Performance

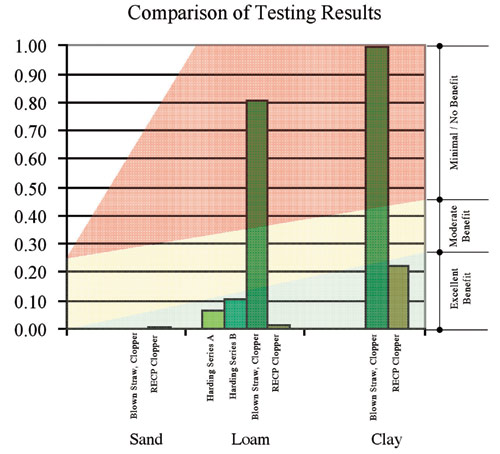

In the case of RECPs, a very rigorous series of evaluations has been developed and implemented. Testing and research that the RECP industry utilizes has proven to be a major catalyst in the overall increase in confidence and use of the technology. Detailed testing has been conducted on virtually hundreds of products under various conditions and protocols. Testing for slope installations has focused on the ability of the RECP to mitigate the forces rainfall and runoff while maintaining soil in place. Several facilities throughout the country are configured and utilized for testing. ASTM International maintains a refereed standard (D6459) for the large-scale evaluation of RECPs performance on a slope. The ASTM standard requires the product to be tested on a 3:1 (H:V) slope and be subjected to a series of controlled rainfall events while monitoring sediment migration and runoff. The ASTM standard provides a consistent methodology for testing and a means of comparison to evaluate competing products and technologies. In addition to the ASTM standard, implementation of approved product programs on the state and federal level typically requires testing by alternate protocols. Conversely, practices utilizing nonmanufactured materials or in-field techniques have not been evaluated under the same scrutiny. Many states do not require quantified performance testing of nonmanufactured techniques, nor associate any performance limits to the practice. However, over the course of the development of erosion control techniques, many practices have been evaluated by field trials or simulated conditions applied to field installations. Testing of many practices has been conducted on available plots of land, subjected to whatever storms nature provided. In the case of Blown Straw, values for the performance of the technique have been published by the Center for Watershed Protection (CWP), referenced from Harding (1990) and Horner (1990). According to the research conducted, Blown Straw reduced erosion by up to 93.2%. Two specific tests were cited utilizing differing evaluation methods. Performance of an erosion control practice on a slope typically is dependent on the rainfall energy, slope grade, slope length and the soil type utilized for testing. Further, performance may vary if the application is exposed to minimal rainfall. A study was conducted to evaluate the performance of Blown Straw versus a typical RECP, utilizing identical testing methods. In order to determine the potential for Blown Straw to be used as a replacement for RECPs, the RECP testing protocol, ASTM D6459 was employed. Blown Straw was applied to the test plot at a rate of 2,837 kg/Ha (2,500 pounds per acre). An RECP consisting of a single netted, temporary Erosion Control Blanket (ECB) was utilized for the comparison. The ECB was rolled onto the plot and secured to the ground surface using metal U-staples. Staples were positioned in accordance with the manufacturer’s guidelines. Each practice was evaluated under identical conditions, on three soil types. Simulated rainfall was produced at three intensities 51, 102 and 154 mm/hr (2, 4 and 6 inches per hour). Each installation was exposed to increasing rainfall intensities to allow for the quantification of performance. Figure 2 As each simulated rainfall event was generated, runoff from each test plot was collected. Runoff was evaluated to determine the total sediment yield and water volume from each plot. Unprotected plots were tested identically as a reference. Sediment yield from each protected plot was compared to the reference plot of the same soil type to determine the percentage sediment yield reduction. Sediment yield reduction was normalized with respect to the actual recorded volume and duration of the simulated rainfall event for each plot. Figure 2 provides a visual graphic of the results as presented by Clopper et al compared with values reported by Harding and Horner. The dramatic difference in performance of the two systems is evident in Figure 2. Blown Straw was effective on the sand soil and on shallow slopes consisting of loam soil. However, Blown Straw provided little benefit on the steep slopes, and no measurable benefit on clay soil. Blown Straw showed an overall lack of utility on slopes without the potential to freely drain, which was contradictory to other work. Typically, Blown Straw is specified as a very effective erosion control practice. In testing Blown Straw by more rigorous methodologies, the thresholds of performance for Blown Straw become apparent. Comparing the results from testing of the two methodologies, it becomes evident that the field usefulness of Blown Straw is restricted to shallow slope, low risk environments. Applied to steeper slopes and exposed to significant rainfall and runoff, Blown Straw provides minimal benefit as an erosion control practice.

In contrast, the RECP was over 98% effective on both the sand and loam plots and reduced erosion on the clay plot by nearly 80%. As RECPs represent a technology that is developed from intelligence in engineering and consistency in quality, the benefits realized where the raindrops meet the slope were not surprising. RECPs provide mechanical restraint to the incorporated mulch material and are secured to the soil surface. Thus, RECPs afford greater resistance to runoff and minimize displacement of mulch material. Conclusion

Evaluation of the research conducted and reviewed, shows the advantage and improved performance of manufactured materials compared to Blown Straw. Comparison of testing results showed significantly greater performance of manufactured materials when installed on slopes developing runoff. Further, RECPs were shown to have greater utility on steep slopes. Considering the performance advantages, flexibility in design and application, manufactured quality control and minimal cost difference, RECPs show significant value as erosion control practice compared to Blown Straw. For more information or an unedited version of this paper, including all tables, contact Laurie Honningford, e-mail: laurie@ectc.org. Acknowledgements References Clopper, P.E., Vielleux, M., Johnson, T., “Quantifying the Performance of Hillslope Erosion Control Best Management Practices:, ASCE 2001. Harding, M.V. 1990. “Erosion Control Effectiveness: Comparative Studies of Alternative Mulching Techniques.”, In: Environmental Restoration: Science and Strategies for Restoring the Earth. Island Press. Covello, CA 149-156. Horner, R.R. J. Guedry and M.H. Kortenhog. 1990. “Improving the Cost Effectiveness of Highway Construction Site Erosion and Pollution Control.”, Washington State Transportation Center. Federal Highway Administration. Seattle, WA. 79 pp. |

©2006 - 1998 Land and Water, Inc.